Nekukurumidza kukura kwelithium bhatiriindasitiri, mamiriro ekushandisa emabhatiri e-lithium anoramba achiwedzera uye kuva mudziyo unokosha wesimba muhupenyu hwevanhu nebasa.Kana zvasvika pakugadzirwa kwevagadziri velithium bateri, iyo lithium bhatiri yekugadzira nzira inonyanya kusanganisira zvinhu, kuvhara, sheeting, kugadzirira, mhepo, shelling, rolling, kubika, liquid injection, welding, etc. Izvi zvinotevera zvinotanga pfungwa dzinokosha dze iyo lithium bhatiri yekugadzira maitiro.Positive electrode ingredients Iyo yakanaka electrode ye lithiamu mabhatiri inoumbwa nezvinhu zvinoshanda, conductive agents, adhesives, etc. Kutanga, iyo yakasvibiswa inosimbiswa uye yakabikwa.Kazhinji kutaura, conductive agent inoda kubikwa pa ≈120℃ kwemaawa masere, uye inonamira PVDF inoda kubikwa pa ≈80℃ kwemaawa masere.Kunyangwe zvinhu zvinoshanda (LFP, NCM, nezvimwewo) zvinoda kubheka uye kuomeswa zvinoenderana nemamiriro ezvakagadzirwa.Parizvino, iyo general lithium bhatiri workshop inoda tembiricha ≤40 ℃ uye humidity ≤25% RH.Mushure mekuomeswa kwapera, PVDF glue (PVDF solvent, NMP solution) inoda kugadzirirwa pachine nguva.Hunhu hwePVDF glue hwakakosha pakupikisa kwemukati uye kushanda kwemagetsi kwebhatiri.Zvinhu zvinokanganisa kushandiswa kweglue zvinosanganisira tembiricha uye kumhanyisa kumhanya.Iyo yakakwirira tembiricha, iyo yero yeglue inokanganisa kunamatira.Kana kukurumidza kusanganiswa kwakakurumidza, glue inogona kukuvara nyore nyore.Iyo chaiyo yekutenderera kumhanya inoenderana nehukuru hwedhisiki yekuparadzira.Kazhinji kutaura, mutsara wekumhanya kwedhisiki yekuparadzira ndeye 10-15m/s (zvichienderana nemidziyo).Panguva ino, tangi inosanganiswa inofanirwa kuvhura mvura inotenderera, uye kutonhora kunofanira kuva ≤30 ° C.

Wedzera cathode slurry mumabheti.Panguva ino, iwe unofanirwa kubhadhara kune kurongeka kwekuwedzera zvinhu.Kutanga wedzera iyo inoshanda zvinhu uye conductive agent, fambisa zvishoma nezvishoma, wobva wawedzera glue.Nguva yekudyisa uye reshiyo yekudyisa inofanirwawo kunyatsoitwa zvinoenderana neiyo lithium bhatiri yekugadzira maitiro.Chechipiri, kumhanya kwekutenderera uye kutenderera kumhanya kwemidziyo kunofanirwa kudzorwa zvakanyanya.Kazhinji kutaura, kupararira kwemutsara kumhanya kunofanirwa kunge kuri pamusoro pe17m/s.Izvi zvinoenderana nekushanda kwechigadzirwa.Vagadziri vakasiyana vanosiyana zvakanyanya.Dzorawo vacuum uye tembiricha yekusanganisa.Panguva ino, iyo particle size uye viscosity ye slurry inoda kugara ichionekwa.Iyo particle size uye viscosity yakabatana zvakanyanya kune yakasimba yemukati, zvinhu zvivakwa, kudyisa kutevedzana uye lithium bhatiri yekugadzira maitiro.Panguva ino, maitiro echinyakare anoda tembiricha ≤30 ℃, humidity ≤25% RH, uye vacuum degree ≤-0.085mpa.Chinja slurry kune tangi yekufambisa kana chitoro chepende.Mushure mekunge slurry yaendeswa kunze, inoda kuongororwa.Chinangwa ndechekusefa zvimedu zvakakura, kunayisa uye kubvisa ferromagnetic nezvimwe zvinhu.Zvimedu zvakakura zvinokanganisa kupfeka uye zvinogona kukonzera kunyanyisa kuzviburitsa kwebhatiri kana njodzi yepfupi pfupi;yakawandisa ferromagnetic zvinhu muslurry inogona kukonzera yakawandisa kuzviburitsa kwebhatiri uye kumwe kukanganisa.Izvo zvinodiwa zveiyi lithium bhatiri yekugadzira maitiro ndeiyi: tembiricha ≤ 40 ° C, humidity ≤ 25% RH, sikirini mesh size ≤ 100 mesh, uye particle size ≤ 15um.

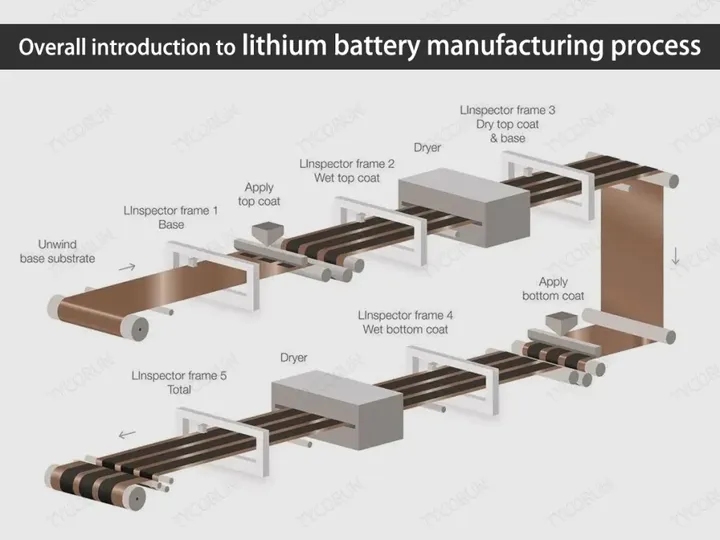

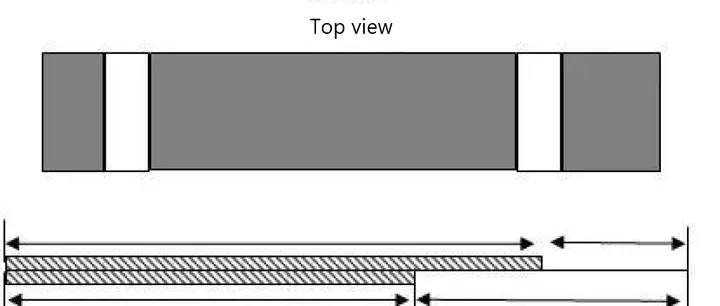

Negative electrodezvinosanganisa Iyo yakaipa electrode yelithium bhatiri inoumbwa nezvinhu zvinoshanda, conductive agent, binder uye dispersant.Kutanga, simbisa iyo mbishi zvinhu.Yechinyakare anode system imvura-based mixing process (the solvent is deionized water), saka hapana zvakakosha zvekuomeswa zvinodiwa pazvimisikidzo.Iyo lithium bhatiri yekugadzira maitiro inoda kuti conductivity yemvura yakasvibiswa ive ≤1us/cm.Zvido zvemusangano: tembiricha ≤40℃, humidity ≤25%RH.Gadzirira glue.Mushure mekunge zvigadzirwa zvatemwa, glue (inoumbwa neCMC nemvura) inofanira kutanga yagadzirwa.Panguva ino, dururira graphite C uye conductive agent mumusanganisi wekusanganisa yakaoma.Zvinokurudzirwa kuti usabvisa kana kuvhura mvura inotenderera, nekuti zvimedu zvinoburitswa, kukwizwa uye kupisa panguva yekusanganiswa kwakaoma.Iyo yekutenderera inomhanya yakaderera kumhanya 15 ~ 20rpm, kukwenya uye kugaya kutenderera ndeye 2-3 nguva, uye nguva yepakati ndeye ≈15min.Dururira glue mumusanganisi uye tanga kupukuta (≤-0.09mpa).Sveta rabha pakumhanya kwakaderera kwe15 ~ 20rpm kwekaviri, wozogadzirisa kumhanya (yakaderera kumhanya 35rpm, yakakwira 1200 ~ 1500rpm), uye kumhanya kweinenge 15min ~ 60min maererano nekunyorova kwemugadziri wega wega.Pakupedzisira, dururira SBR mu blender.Yakaderera kumhanya inosimudzira inokurudzirwa sezvo SBR iri refu cheni polymer.Kana iyo yekutenderera ichimhanya zvakanyanya kwenguva yakareba, iyo molecular cheni inotsemuka nyore uye kurasikirwa nebasa.Inokurudzirwa kumutsa nekumhanya kwakaderera kwe35-40rpm uye kumhanya kwe1200-1800rpm kwemaminetsi gumi-20.Test viscosity (2000 ~ 4000 mPa.s), particle size (35um≤), yakasimba content (40-70%), vacuum degree uye screen mesh (≤100 mesh).Yakananga maitiro maitiro achasiyana zvichienderana nehunhu hwezvinhu uye kusanganisa maitiro.Iyo musangano inoda tembiricha ≤30 ℃ uye humidity ≤25% RH.Coating cathode coating Iyo lithium bhatiri yekugadzira process inoreva kuburitsa kana kupfapfaidza iyo cathode slurry paAB pamusoro pearuminiyamu inounganidza ikozvino, ine imwechete yepamusoro density ye ≈20 ~ 40 mg/cm2 (ternary lithium bhatiri mhando).Tembiricha yechoto kazhinji iri pamusoro pe4 kusvika ku8 mapfundo, uye tembiricha yekubikira yechikamu chega chega inogadziriswa pakati pe95 ° C uye 120 ° C zvichienderana nezvinodiwa chaizvo kudzivirira kutsemuka kwakachinjika uye kudonha kwesolvent panguva yekupwanya kwekubika.Iyo yekuchinjisa coating roller yekumhanyisa reshiyo ndeye 1.1-1.2, uye gap chinzvimbo chakatetepa ne20-30um kudzivirira yakawandisa compaction yeiyo label chinzvimbo nekuda kwemuswe panguva yebhatiri bhasikoro, izvo zvinogona kutungamirira kune lithium kunaya.Coating unyoro ≤2000-3000ppm (zvichienderana nezvinhu uye maitiro).Iyo yakanaka electrode tembiricha mumusangano ndeye ≤30 ℃ uye hunyoro ndeye ≤25%.Iyo dhiyabhorosi dhizaini ndeiyi inotevera: Schematic dhayagiramu yematepi yekuputira

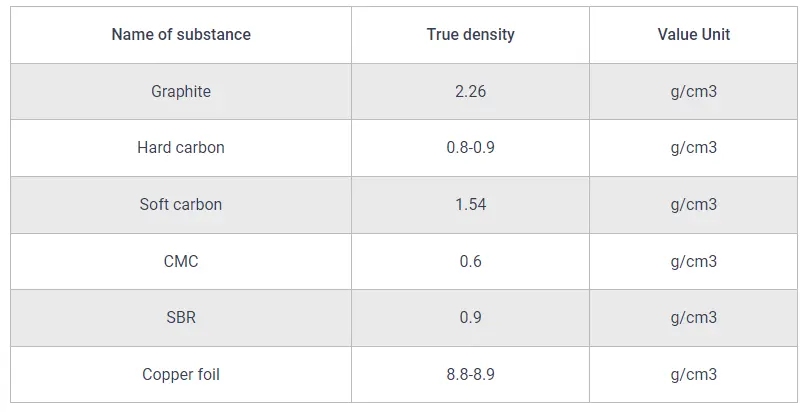

Thelithium bhatiri kugadziraprocess yenegative electrode coatingzvinoreva extruding kana kupfapfaidza negative electrode slurry paAB pamusoro pemuunganidzi wemhangura.Single surface density ≈ 10 ~ 15 mg / cm2.Iyo tembiricha yekubikira yevira kazhinji ine zvikamu 4-8 (kana kupfuura), uye tembiricha yekubikira yechikamu chimwe nechimwe i80 ℃ ~ 105 ℃.Inogona kugadziridzwa maererano nezvinodiwa chaizvo kuti udzivise kubikira kuputika uye kutsemuka kwakachinjika.Iyo yekumhanyisa roller yekumhanyisa reshiyo ndeye 1.2-1.3, gaka rakatetepa 10-15um, iyo pendi yekumisikidza iri ≤3000ppm, yakashata electrode tembiricha mumusangano i ≤30 ℃, uye humidity ≤25%.Mushure mekuputirwa kwakanaka kweplate yakanaka yakaoma, dhiramu inoda kurongeka mukati menguva yekugadzira.Iyo roller inoshandiswa kubatanidza iyo electrode sheet (yakawanda yekupfeka pachiyero cheyuniti).Parizvino, kune nzira mbiri dzekutsikirira dzemagetsi mu lithium bhatiri yekugadzira maitiro: kupisa kudzvanya uye kutonhora kudzvanya.Kuenzaniswa nekutsikirira kunotonhora, kupisa kunopisa kune yakakwirira compaction uye yakaderera rebound rate.Nekudaro, iyo inotonhora yekutsikirira maitiro ari nyore uye ari nyore kushandisa nekudzora.Iyo huru yemidziyo ye roller ndeyekuzadzisa zvinotevera maitiro maitiro, compaction density, rebound rate uye elongation.Panguva imwecheteyo, zvinofanirwa kucherechedzwa kuti brittle chips, mapundu akaoma, zvinhu zvakawa, wavy edges, nezvimwewo hazvibvumirwe pamusoro pechigamba chetsvimbo, uye kuputsa hakubvumidzwe mumakumbo.Panguva ino, tembiricha yewekishopu: ≤23 ℃, humidity: ≤25%.Iyo yechokwadi density yezvino zvakajairika zvinhu:

Inonyanya kushandiswa compaction:

Rebound rate: general rebound 2-3 μm

Elongation: Positive electrode sheet inowanzo ≈1.002

Mushure mokunge mupumburu wakanaka we electrode wapera, danho rinotevera nderokuparadzanisa chidimbu che electrode muzvikamu zviduku zvehupamhi hwakafanana (hunoenderana nehurefu hwebhatiri).Paunenge uchitsemura, teerera kune mabhura echigamba.Izvo zvinodikanwa kuti unyatsoongorora zvidimbu zvepango zvemaburrs mune X uye Y nzira nerubatsiro rwemaviri-dimensional michina.Longitudinal burr kureba maitiro Y≤1/2 H diaphragm ukobvu.Tembiricha yakadzika yewekishopu inofanirwa kunge iri ≤23 ℃, uye nzvimbo yedova inofanira kunge iri ≤-30 ℃.Iyo nzira yekugadzira yeasinage electrode sheets yelithium bhatiri negative electrode sheets yakafanana neyeyakanaka electrode, asi maitiro ekugadzira akasiyana.Tembiricha yeambient yewekishopu inofanirwa kunge iri ≤23 ℃ uye hunyoro hunofanirwa kunge huri ≤25%.Chokwadi density yezvakajairika negative electrode zvinhu:

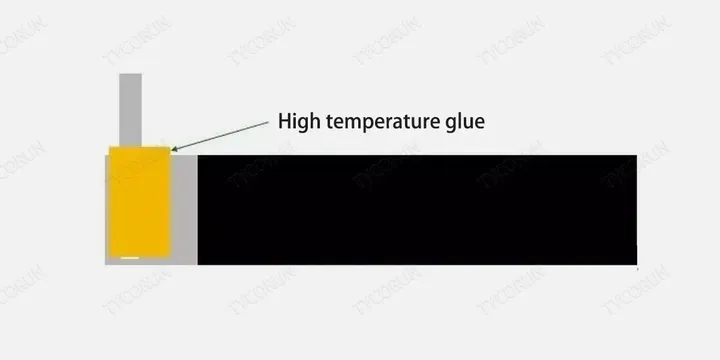

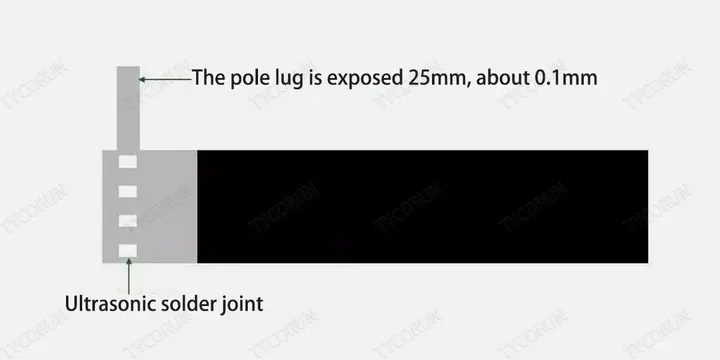

Inowanzo shandiswa negative electrode compaction: Rebound rate: General rebound 4-8um Elongation: Positive plate kazhinji ≈ 1.002 Nzira yekugadzira lithium battery positive electrode stripping yakafanana neyakanaka electrode stripping process, uye zvese zvinoda kudzora maburrs muX uye Y nzira.Tembiricha yakadzika yewekishopu inofanirwa kunge iri ≤23 ℃, uye nzvimbo yedova inofanira kunge iri ≤-30 ℃.Mushure mokunge ndiro yakanaka yakagadzirira kubviswa, ndiro yakanaka inoda kuomeswa (120 ° C), uye ipapo pepa realuminium rinosungirirwa uye rakaputirwa.Panguva iyi, kureba kwetabhu uye hupamhi hwekuumba hunofanirwa kutariswa.Tichitora **650 dhizaini (senge bhatiri re18650) semuenzaniso, dhizaini ine ma tabo akafumurwa inonyanya kufunga nezvekubatana kwakanaka kwema cathode ma tabo panguva ye cap uye roll groove welding.Kana mabheti ematanda akafumurwa kwenguva yakareba, dunhu pfupi rinogona kuitika zviri nyore pakati pematabhu ematanda negoko resimbi panguva yekutenderedza.Kana bhegi racho rakanyanya kupfupika, kapu haigone kutengeswa.Parizvino, kune marudzi maviri e ultrasonic welding misoro: linear uye point-shaped.Maitirwo emumba anonyanya kushandisa mitsetse welding misoro nekuda kwekufunga kwe overcurrent uye welding simba.Mukuwedzera, guru-tembiricha guru rinoshandiswa kuvhara mashizha ekutengesa, kunyanya kudzivirira njodzi yemapfupi mafupi anokonzerwa nesimbi burrs uye marara esimbi.Iyo ambient tembiricha yewekishopu inofanirwa kunge iri ≤23 ℃, iyo dova inofanirwa kunge iri ≤-30 ℃, uye cathode mwando wemukati unofanirwa kunge uri ≤500-1000ppm.

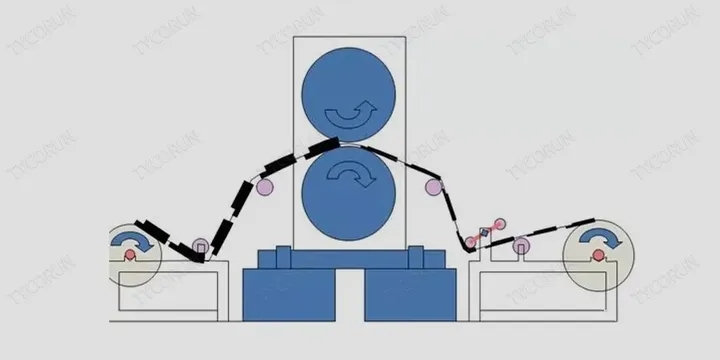

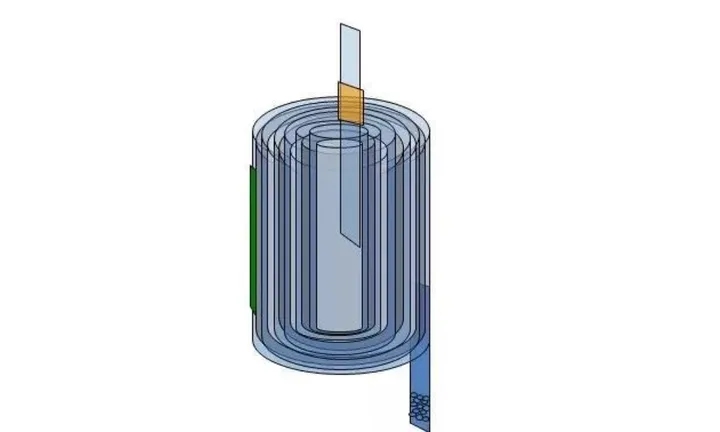

Negative Plate PreparationIyo ndiro yakashata inoda kuomeswa (105-110 ° C), ipapo mapepa e nickel anosungirirwa uye akaputirwa.Solder tebhu kureba uye kuumba hupamhi zvakare inofanirwa kutariswa.Iyo ambient tembiricha yewekishopu inofanirwa kunge iri ≤23 ℃, nzvimbo yedova inofanira kunge iri ≤-30 ℃, uye hunyoro hweiyo yakaipa electrode inofanira kunge iri ≤500-1000ppm.Kupeperetsa ndiko kufambisa mhepo yekuparadzanisa, pepa re electrode yakanaka uye shiti re electrode richipinda musimbi yesimbi kuburikidza nemuchina unomonereka.Nheyo yacho ndeyekuputira iyo yakanaka electrode neiyo negative electrode, uye wozoparadzanisa maelectrode akanaka uye asina kunaka kuburikidza nekuparadzanisa.Sezvo iyo yakaipa electrode yemaitiro echinyakare ndiyo inodzora electrode yebhatiri dhizaini, dhizaini dhizaini yakakwira kupfuura iyo yakanaka electrode, kuitira kuti panguva yekugadzira kuchaja, iyo Li + yeiyo yakanaka electrode inogona kuchengetwa mu "vacancy" ye. iyo negative electrode.Kunyanya kutarisisa kunoda kubhadharwa kune inotenderedza tension uye pole chidimbu kuronga kana uchimonyoroka.Kunyanya kudiki kupeta tension kuchakanganisa kupikisa kwemukati uye chiyero chekuisa imba.Kunyanya kunetseka kunogona kutungamira kune njodzi yekupfupika kwedunhu kana chipping.Alignment inoreva chinzvimbo cheiyo negative electrode, positive electrode, uye separator.Iyo yakafara ye electrode yakaipa ndeye 59.5 mm, iyo electrode yakanaka ndeye 58 mm, uye separator i 61 mm.Iwo matatu anoenderana panguva yekutamba kudzivirira njodzi yemapfupi maseketi.Kupokana kwemhepo kunowanzo kuve pakati pe0.08-0.15Mpa yedanda rakanaka, 0.08-0.15Mpa yedanda rakashata, 0.08-0.15Mpa yekumusoro diaphragm, uye 0.08-0.15Mpa yezasi diaphragm.Kugadziriswa kwakananga kunoenderana nemidziyo uye maitiro.Tembiricha yakadzika yewekishopu iyi ≤23℃, nzvimbo yedova iri ≤-30℃, uye hunyoro huri ≤500-1000ppm.

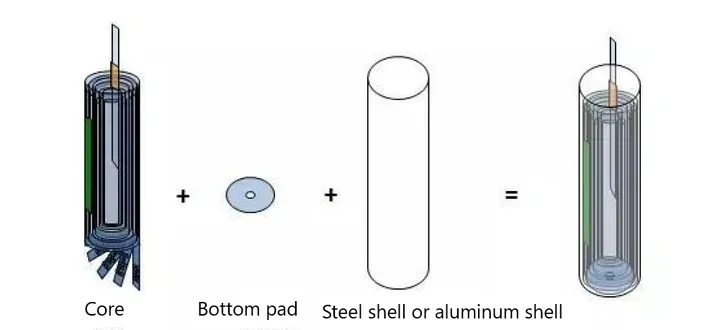

Isati yaiswa bhatiri musimboti mukesi, bvunzo yeHi-Pot ye200 ~ 500V inodiwa (kuti uedze kana bhatiri repamusoro-voltage rakapfupika-inotenderera), uye vacuum inodiwawo kuti uwedzere kudzora guruva usati waiswa mukati. nyaya yacho.Iwo matatu mahombe ekudzora mabhatiri e lithium hunyoro, burrs uye guruva.Mushure mekunge maitiro apfuura apera, isa gasket rezasi muzasi pebhatiri musimboti, kotamisa iyo yakanaka electrode sheet kuitira kuti nzvimbo yakatarisana nebhatiri musimboti unomonereka pinhole, uye wozopedzisira waiisa yakatwasuka musimbi shell kana aluminium shell.Kutora mhando 18650 semuenzaniso, iyo yekunze dhayamita ≈ 18mm + kureba ≈ 71.5mm.Kana iyo nzvimbo yepakati-yepakati yepakati yeronda iri diki pane yemukati-yepakati-chikamu nzvimbo yesimbi kesi, iyo simbi kesi yekuisa mwero inosvika 97% kusvika 98.5%.Nekuti iyo rebound kukosha kwechigamba uye dhigirii rekupinda kwemvura panguva yejekiseni rekupedzisira rinofanira kutariswa.Iyo nzira yakafanana neyepasi pasi pasi inosanganisira kuungana kwepamusoro underlayment.Tembiricha yakadzika yewekishopu inofanirwa kunge iri ≤23 ℃, uye nzvimbo yedova inofanira kunge iri ≤-40 ℃.

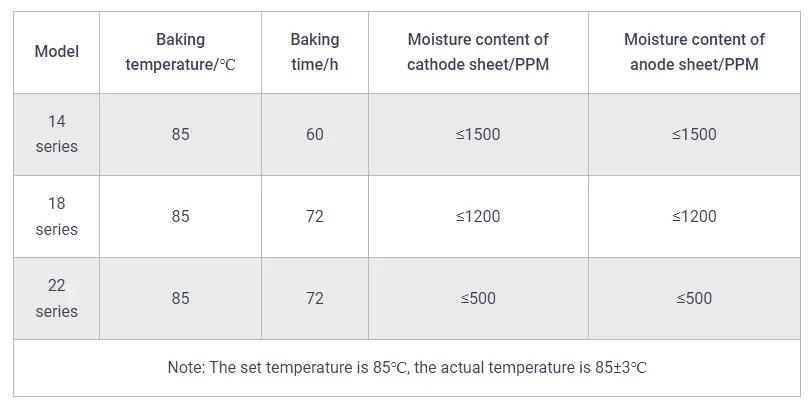

Rollinginopinza pini ye solder (inowanzo gadzirwa nemhangura kana alloy) pakati peiyo solder core.Inowanzo shandiswa welding pini ndeye Φ2.5 * 1.6mm, uye simba rekushongedza re electrode risina kunaka rinofanira kuva ≥12N kuti rive rakakodzera.Kana yakanyanya kuderera, inokonzeresa zviri nyore solder uye yakawandisa yemukati kuramba.Kana yakanyanya kukwirisa, zviri nyore kupinza nickel layer iri pamusoro pegoko resimbi, zvichikonzera majoini anotengeswa, zvichitungamira kune njodzi dzakavanda dzakadai se ngura uye kubuda.Manzwisisiro akareruka ekutenderedza groove ndeyekugadzirisa ronda rebhatiri musimboti pane casing pasina kuzununguka.Mukugadzira iyi lithium bhatiri, kutarisisa kwakanyanya kunofanirwa kubhadharwa pakuenderana kweiyo transverse extrusion kumhanya uye longitudinal kudzvanya kumhanya kuti udzivise kucheka casing payakanyanya kuchinjika kumhanya, uye nickel layer yenotch inodonha kana. iyo longitudinal kumhanya inokurumidza kana kureba kwenoti kuchakanganiswa uye kuiswa chisimbiso kuchakanganiswa.Izvo zvinodiwa kuti utarise kana maitiro ekudzika kwegroove kudzika, kuwedzera uye groove kureba zvinoenderana nezviyero (nekuita uye theoretical kuverenga).Saizi dzakajairika hobho i1.0, 1.2 uye 1.5 mm.Mushure mekunge groove yapera, muchina wese unofanirwa kugezwa zvakare kudzivirira tsvina yesimbi.Iyo vacuum degree inofanira kunge iri ≤-0.065Mpa, uye nguva yekutsvaira inofanira kunge iri 1 ~ 2s.Iyo ambient tembiricha zvinodiwa zvewekishopu iyi ≤23 ℃, uye nzvimbo yedova iri ≤-40 ℃.Battery core baking Mushure mekunge cylindrical bhatiri mapepa akakungurutswa uye grooved, inotevera lithium bhatiri yekugadzira maitiro yakakosha: kubika.Panguva yekugadzirwa kwemasero ebhatiri, imwe huwandu hwehunyoro hunounzwa.Kana hunyoro husingagone kudzorwa mukati meyero yakajairwa nenguva, kuita uye kuchengetedzeka kwebhatiri kuchakanganiswa zvakanyanya.Kazhinji, otomatiki vacuum oven inoshandiswa kubheka.Ronga masero kuti abikwe zvakanaka, isa desiccant muchoto, isa zvigadziro, uye usimudze kutonhora kusvika 85 ° C (kutora lithium iron phosphate mabhatiri semuenzaniso).Izvi zvinotevera zviyero zvekubheka kune akati wandei akasiyana zvirevo zvemasero ebhatiri:

Liquid JekiseniIyo lithium bhatiri yekugadzira maitiro inosanganisira humidity kuyedzwa kweakabikwa bhatiri maseru.Chete mushure mekusvika kune yakapfuura yekubheka zviyero iwe unogona kuenderera kune inotevera nhanho: jekiseni iyo electrolyte.Kurumidza isa mabhatiri akabikwa mubhokisi revacuum girovhosi, kuyera uye kurekodha huremu, isa pamukombe wejekiseni, uye wedzera huremu hwakagadzirirwa hwe electrolyte mukapu (kazhinji bvunzo yebhatiri yakanyudzwa inoitwa: isa bhatiri mukapu. pakati).Isa bhatiri musimboti muelectrolyte, inyure kwenguva yakati rebei, edza iyo yakanyanya kunyura mvura yebhatiri (kazhinji kuzadza mvura zvinoenderana nevhoriyamu yekuyedza), isa mubhokisi rekutsvaira kuti ubvise (vacuum degree ≤ - 0.09Mpa), uye mhanyisa kupinda kwe electrolyte mu electrode.Mushure mekutenderera kwakati wandei, bvisa zvidimbu zvebhatiri uye uzviyere.Verenga kana vhoriyamu yejekiseni inosangana nemutengo wekugadzira.Kana iri shoma, inoda kuzadzikiswa.Kana pane zvakawandisa, ingodurura zvakawandisa kusvika wasangana nezvinodiwa zvekugadzira.Iyo girovhosi bhokisi nharaunda inoda tembiricha ≤23 ℃ uye dova point ≤-45 ℃.

WeldingMunguva iyi yekugadzira lithium bhatiri, chivharo chebhatiri chinofanirwa kuiswa mubhokisi regirovhosi pachine nguva, uye chivharo chebhatiri chinofanirwa kugadzikwa pane yakaderera mold yemuchina wekurudyi neruoko rumwe, uye bhatiri repakati rinofanira kubatwa nerumwe ruoko. ruoko.Gadzirisa bag rakanaka rebhatiri cell neterminal lug yebutiro.Mushure mekusimbisa kuti iyo yakanaka terminal lug inowirirana necap terminal lug, tsika pamushini we ultrasonic welding.Wobva watsika chinja chetsoka chemuchina wewelding.Mushure mezvo, iyo bhatiri unit inofanirwa kuongororwa zvizere kuti itarise iyo welding mhedzisiro ye solder tabo.

Tarisa uone kana solder tebhu dzakabatana.

Dhonza zvinyoro nyoro pane solder tab kuti uone kana yakasununguka.

Mabhatiri ane chivharo chebhatiri chisina kusungwa zvakasimba anoda kukwizwa zvakare.

Nguva yekutumira: May-27-2024